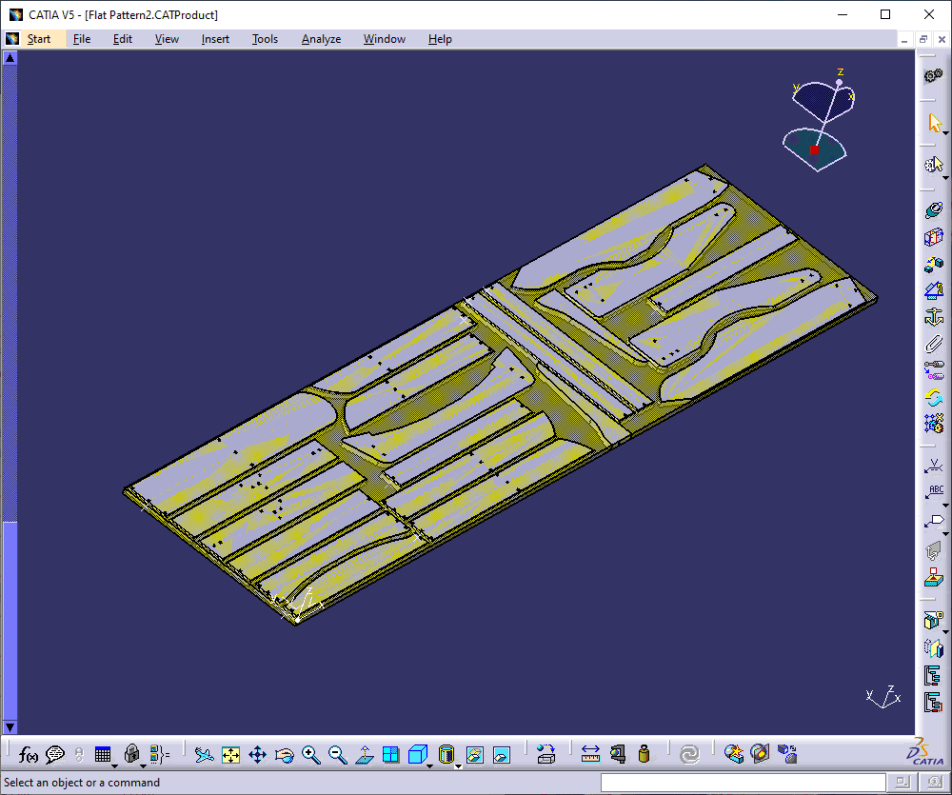

Previously a client was using CATIA® to create a CATProduct containing a 4x8 honeycomb sheet. They would then manually insert each detail part of the asset (of similar type and thickness) into the product, and manually constraining them to be 2" apart, then manually add tabb for each part. They would then manually NC Program the entire assembly.

This method was fine when the furniture was standardized. However they could not keep up with the NC workload once the company switched to custom interiors.

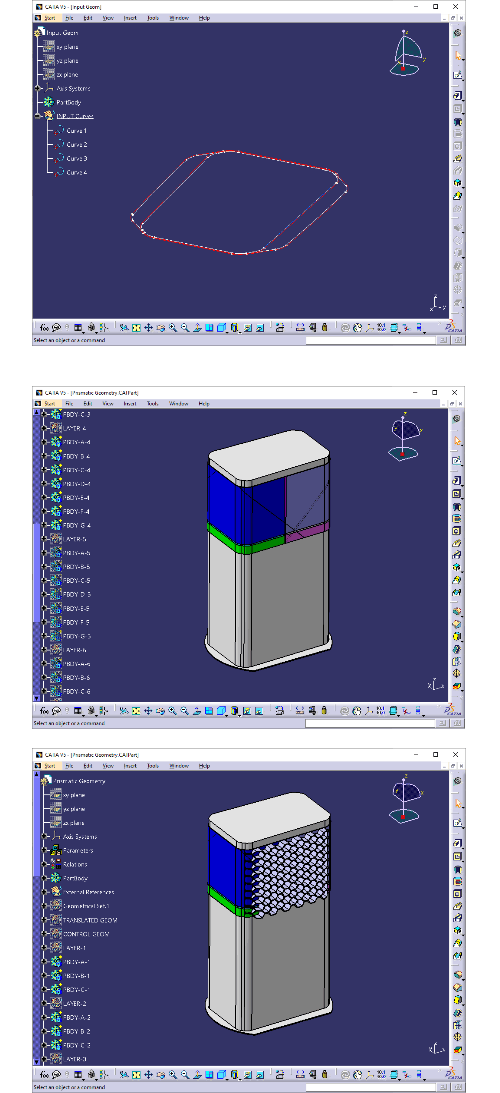

The solution was to create an NC library of all parts, write a series of VB.net programs to control all manufacturing data from start to finish, and generate automatic assembly diagram to show insert type and locations. Data flow was:

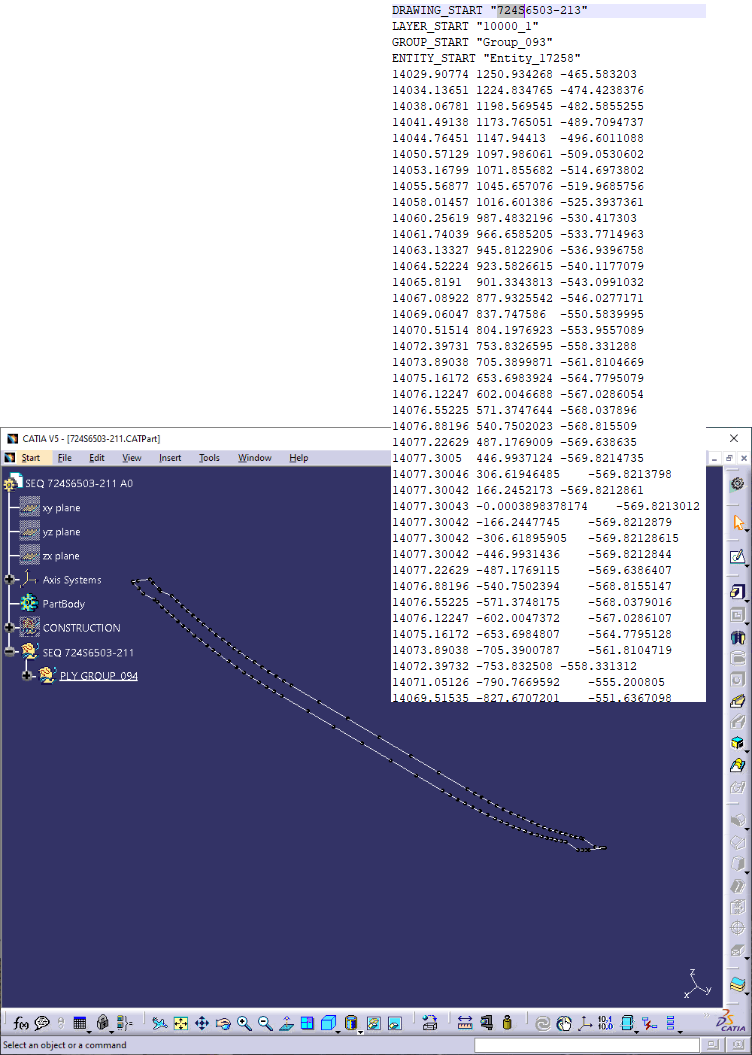

1. Read in Asset in CATIA® V5 and auto determine what parts are not in the current library.

2. Parts not in Library are put in an NC queue

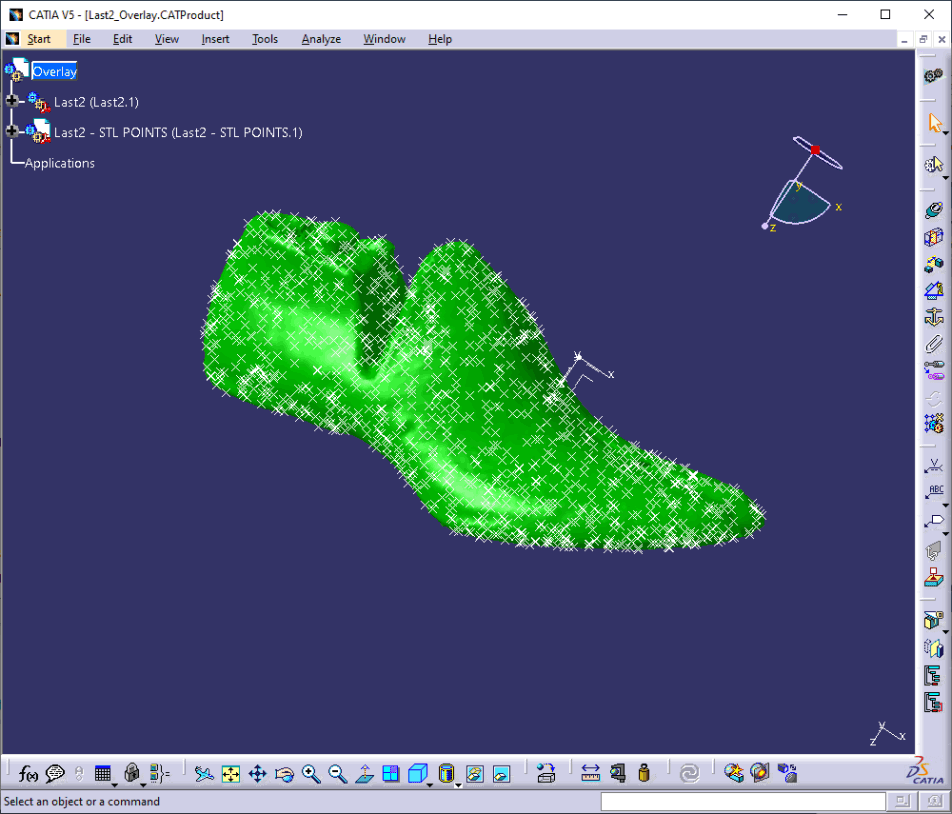

3. NC has a program to translate part to local system and auto create Associated CATProcess. CATProduct with Engineering, Stock, tabs and a not to exceed frame. All components for Vericut are auto created.

4. Fnished programmed Parts are put on an NC Check Queue

5. Once checked, parts are added to the master library.

6. As needed, Individual parts are then automatically nested. Vericut data for the New assembly is then created for a final AutoDiff and collision check. Min Z values are verified for no table crashes. Gcode is then sent to the shop